Valve Regulated Lead Acid (VRLA) Battery Monitoring System

What's the Application of VRLA Lead-acid Battery Monitor System?

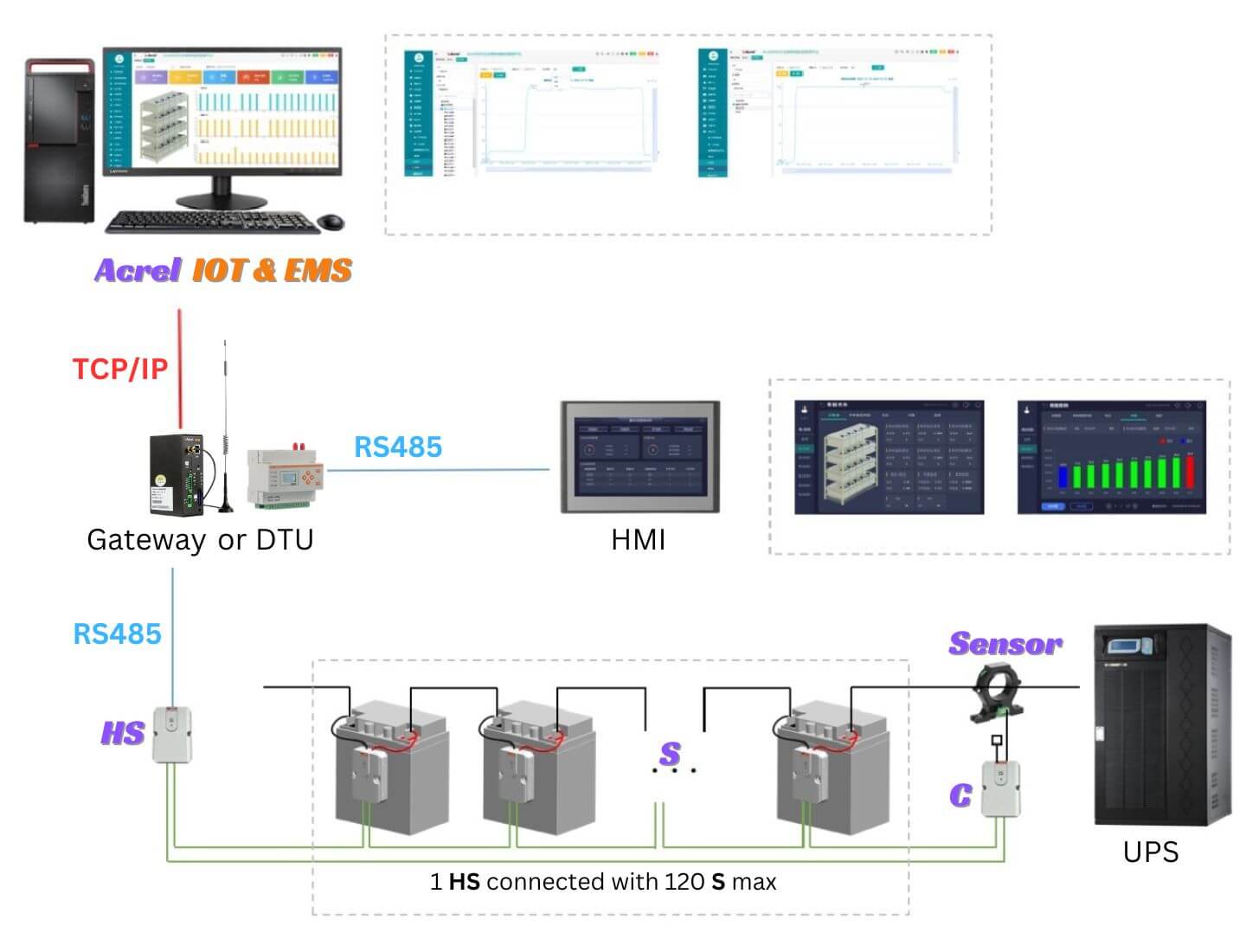

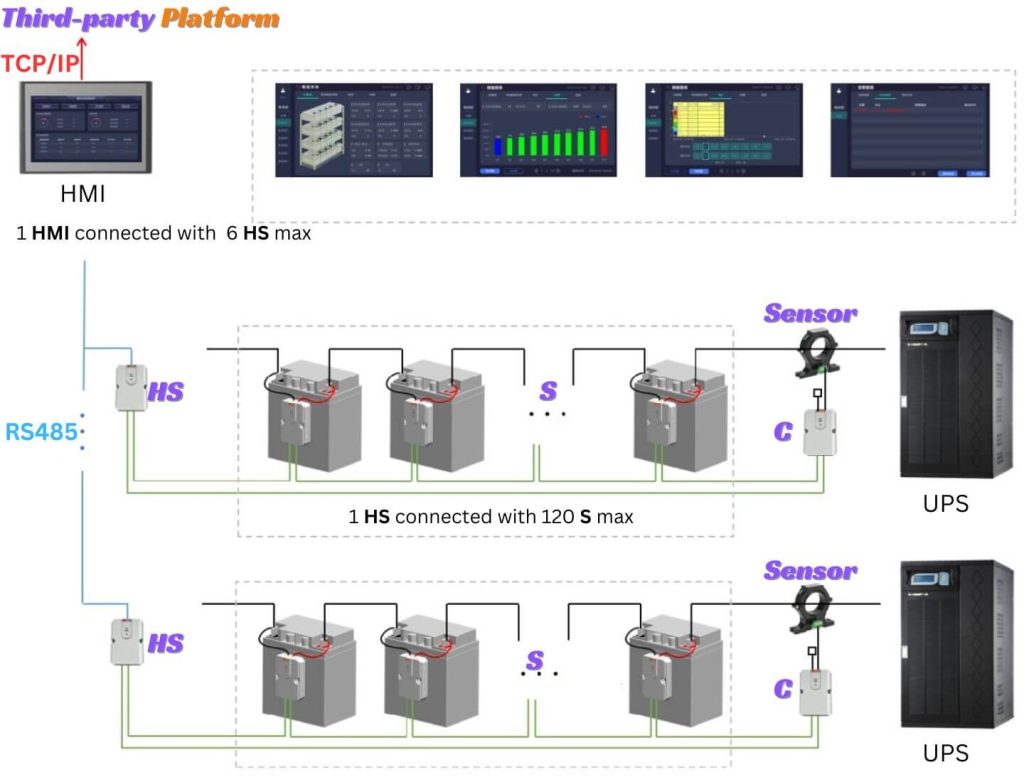

What's the Solution for VRLA Lead-acid Battery 2V 6V 12V?

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

If the aging batteries are not detected and adjusted regularly, the capacity of the battery pack will decrease, the battery life will be shortened, and the efficient and safe operation of the system will be affected.

In order to ensure the actual capacity of the battery pack and the safe operation of the DC system, the use of the battery intelligent detection system (BMS) to detect the capacity of the single battery, identify the failed single battery, and activate the lagging single battery is obviously an important task of battery maintenance and detection.

Initially a battery pack may have well-matched cells, but over time, the cell-to-cell similarity further degrades, not just due to self-discharge, but also impacted from charge/discharge cycling, elevated temperature, and general calendar aging.

How important is VRLA Lead-acid Battery Monitoring?

What Causes VRLA Lead-acid Battery failure?

How do battery management systems work?

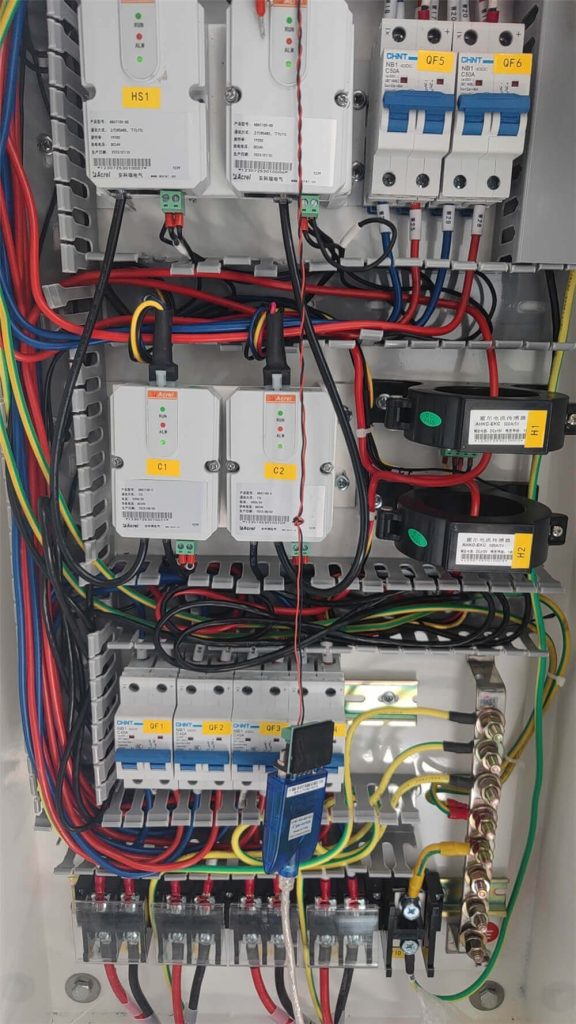

① Electrical Management Protection: Current

② Electrical Management Protection: Voltage

③ Thermal Management Protection: Temperature

④ Capacity Management

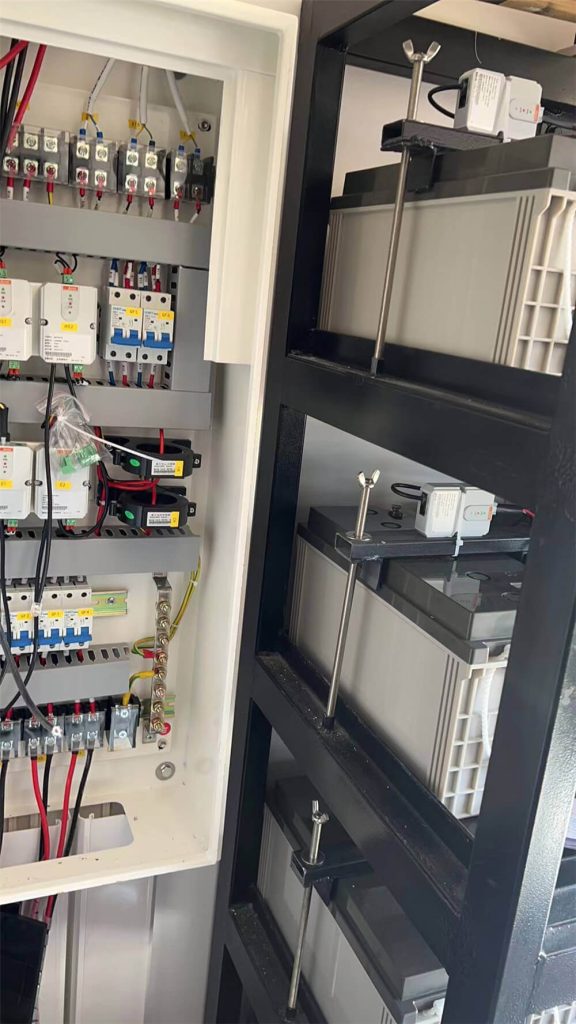

Battery Cell

Battery String

Battery Rack

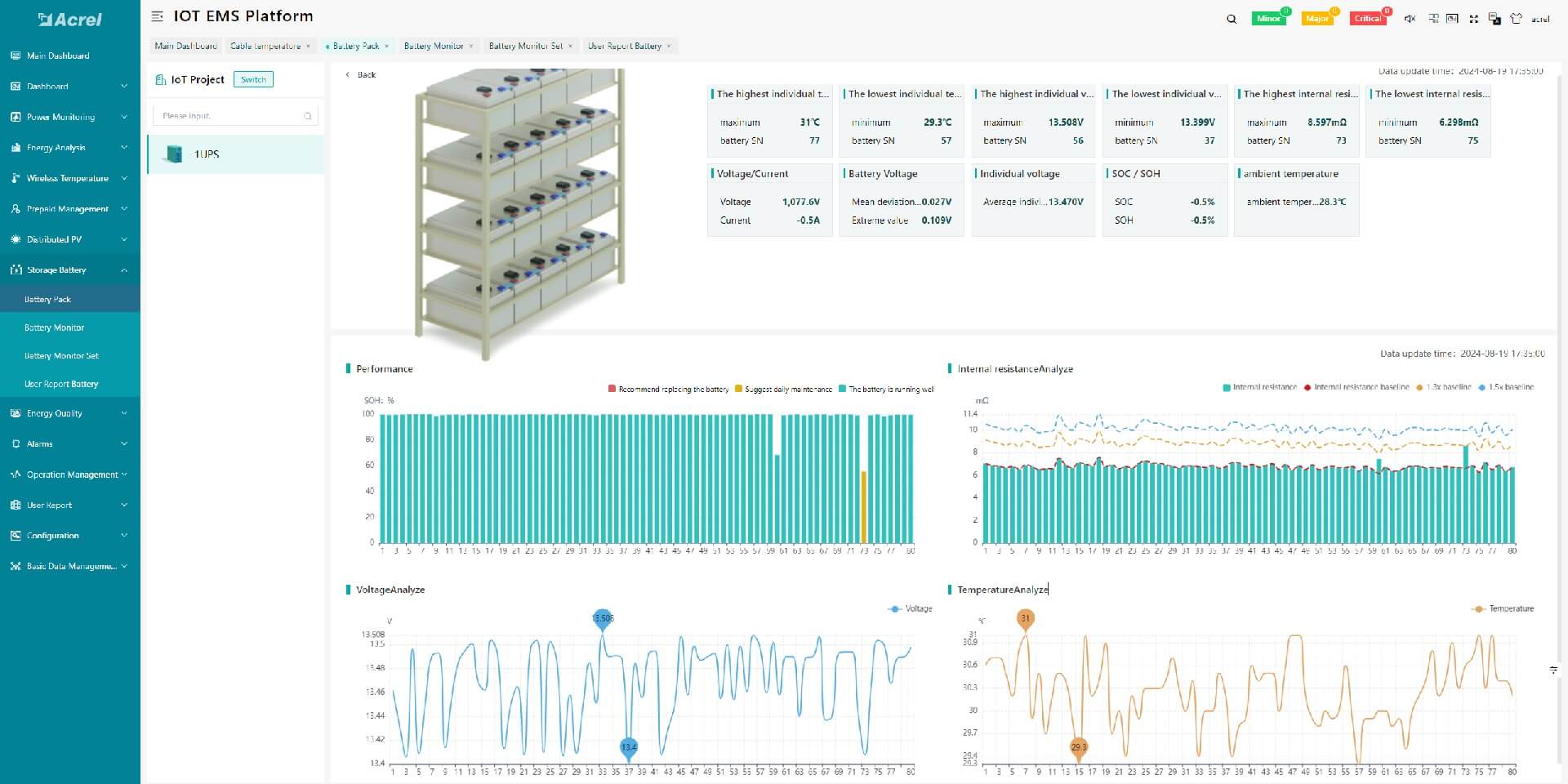

Battery data is collected by the BMS through sensors for real-time analysis

Battery health estimation is also important, with BMS taking into account the overall condition of the battery, like internal consistency and external damage

BMS features the fault warning protection function, that automatically takes action when abnormal battery condition is detected, preventing accidents

Who are Acrel's BMS customers?

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]