In the water conservancy industry, sewage treatment plants and pumping and drainage stations are large consumers of electricity.

Renovating old facilities to improve efficiency, save electricity, tap the potential of energy conservation and emission reduction,

and help achieve carbon peak and carbon neutral goals.

What's the Difficulty of Water Treatment Energy Efficiency Management?

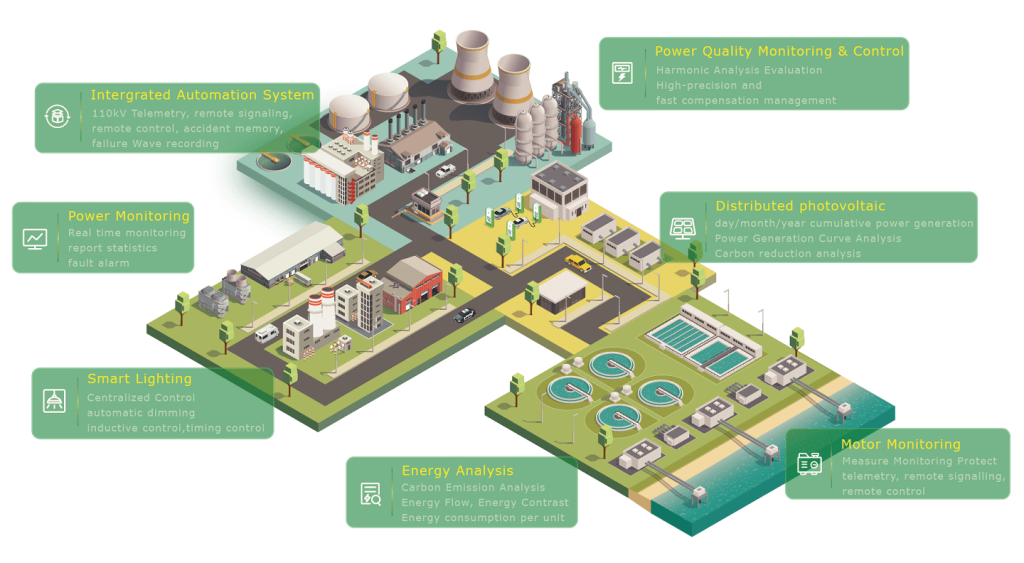

What's the Highlight of Smart Water Treatment Energy Efficiency Management?

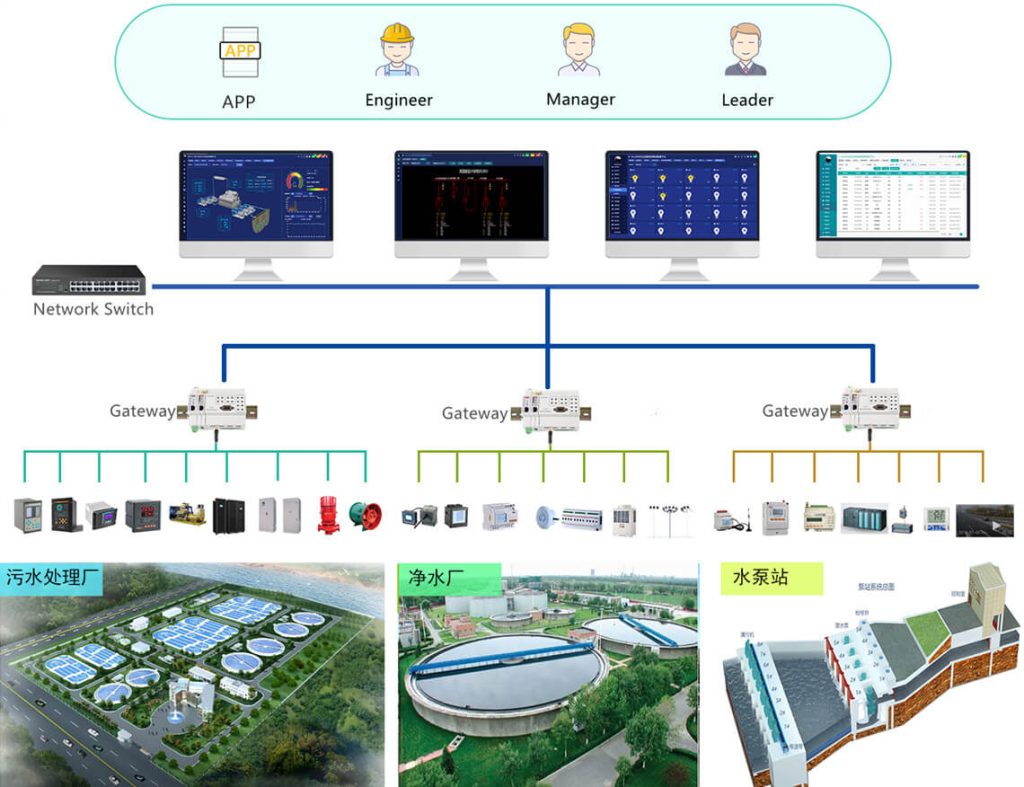

What's the Distribution Structure for Smart Water Treatment Energy Efficiency Management System?

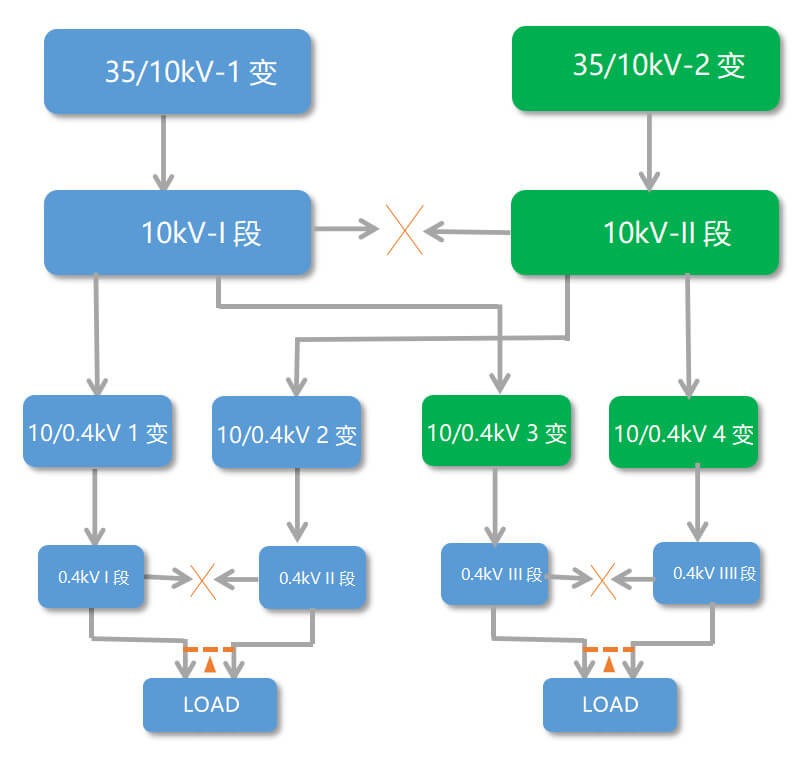

If the power supply of the urban sewage treatment project is interrupted, it will have a serious impact on the life of urban residents and environmental protection.

In order to ensure the continuous and reliable operation of the sewage treatment plant, its electricity load is determined to be Class II.

Two 35kV power sources are led from the upper-level substation to the high-voltage power distribution room of the sewage plant, and the two 10kV power sources are connected in single-female section belts, which can meet the power consumption requirements of the secondary load.

At the same time, in order to ensure the reliability of the power supply, a diesel generator is spared, which can at least meet the power consumption of emergency ventilation, fire fighting, and emergency lighting in the factory.

What's the Smart Water Treatment Energy Efficiency Management Structure?

Energy saving:

Perfect measurement system;

Energy consumption statistics;

Energy flow analysis;

Process production energy consumption data monitoring;

Lighting control;

Load regulation.

Improve power supply reliability:

Real-time monitoring of medium and low voltage;

Power Quality Monitoring and Improvement;

Transformer, generator, process equipment condition monitoring;

Junction temperature monitoring;

Real-time warning.

Operation and maintenance assistance:

Equipment Ledger;

Equipment Maintenance Reminder;

Work order distribution;

Closed-loop operation and maintenance process;

Expert report.

What's the Function of Smart Water Treatment Energy Efficiency Management?

(1) Real time monitoring

Real-time monitoring of high and low voltage power supply and distribution system switch cabinets, transformer microcomputer protection and control devices, generator control cabinets, motors, including remote control, remote signaling, telemetry, remote adjustment, accident alarm and records, etc.

(2) Key power supply and distribution equipment monitoring

Monitor the current, voltage, active/reactive power, power factor, load rate, temperature, three-phase balance, abnormal alarm and other data of transformers, diesel generators, motors, and process equipment.

(3) Fault recording

The system has fault wave recording and event sequence recording, which are used to analyze fault waveforms, assist in analyzing the cause of faults and improve them.

(4) Power Quality Monitoring

Monitor the power quality of each incoming circuit, including data waveform records such as voltage sag, harmonic distortion, flicker, etc., and then judge the disturbance direction of the power distribution system.

(1) Power quality control

Configure active filtering devices and reactive power compensation devices to compensate and control the power quality at the 0.4kV side, and monitor the operation of active filtering devices and reactive power compensation devices to ensure that the power quality meets production requirements.

(2) Electrical fire monitoring

Monitor the leakage current and cable temperature of the power distribution system circuit to realize early warning of water and electrical safety.

(3) Fire-fighting equipment power monitoring and evacuation instructions

Monitor whether the working power of the fire fighting equipment is normal, and ensure that the fire fighting equipment can be put into use normally in the event of a fire.

(4) Node temperature measurement

The system monitors the contact temperature of circuit breakers, busbars, cable connectors, and intensive bus ducts and gives real-time warnings.

(1) Construction of measurement system

Build a metering system for the sewage plant, display energy flow and energy consumption, and help it analyze the whereabouts of energy consumption through the energy flow diagram, and find out abnormal areas of energy consumption.

(2) Energy consumption data statistics

Collect the consumption of factory process electricity, factory service electricity, etc., compare and analyze year-on-year comparisons, calculate total energy consumption and energy intensity, calculate standard coal calculations, and statistical trends of CO2 emissions.

(3) Process energy consumption

Collect the energy consumption of process equipment in the sewage plant, including energy consumption data such as lift pumps, aeration systems, mixing systems, sludge treatment systems, and deodorization systems.

(4) Intelligent lighting control

Single control, area control, automatic control, induction control, timing control, scene control, dimming control and other control methods.

(1) Equipment file management

Configure important equipment including transformers, electrical cabinets, high-voltage cables, air-conditioning hosts, motors and other equipment information, and configure QR codes.

(2) Operation and maintenance process management

Task management, inspection records, defect records, fire alarm records, emergency repair records, notification work orders

(3) Equipment maintenance

After the user maintains the equipment's warranty period and installation time, it detects whether the equipment has been running for a long time or expired, reminds the user to check or replace the corresponding equipment in time, and prompts maintenance or replacement suggestions.

(4) Expert diagnosis report

The system regularly generates energy consumption analysis reports for users and provides expert advice.

2014/35/EU

2014/30/EU

2014/30/EU

EN IEC 61000

IEC 62052

IEC 62053

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

CE

IEC 60947-4-1:2018

IEC 60947-5-1:2016

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

8 current input, 4 voltage input

16 DI, 10 DO

2 RS485, 1 RS232, 1 GPS

Powerful graphic programmable Logic

2014/30/EU

EN IEC 61000

2014/35/EU

EN IEC 61000

EN61010

IEC 61558-1

IEC 61558-2-15

IEC60364-7-710

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]