January 18, 2024

As a part of the urban public transportation system, ailway transportationhas been extensively developed and expanded in the past few decades. It plays an important role in solving urban traffic congestion, reducing environmental pollution, and improving urban sustainability.

With the advancement of science and technology,ailway transportationsystems are constantly introducing new technologies and innovations to improve operating efficiency and passenger experience, save energy and reduce operating costs.

The monitoring of air-conditioning circuits in rail transit train carriages is one of the important aspects to ensure the comfort and safety of passengers in the train. Monitor the electrical parameters of the air conditioning circuit in real time to determine the operating status of the air conditioner, detect potential faults, and take timely measures when power problems occur to ensure the operation of the air conditioning system. At the same time, monitoring data of the air conditioning loop should be recorded for subsequent analysis and trend observation, which can help identify the long-term performance and health of the system.

The specific requirements of air-conditionercircuits on rail transit train are as follows:

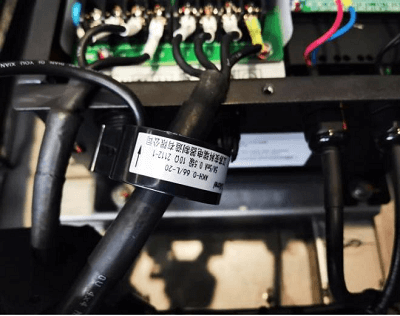

1.1 The train continues to vibrate during operation, so there are higher requirements for the seismic resistance of the monitoring module. The module terminals need to be tightened with screws and pass environmental tests, shock and vibration tests and other related tests;

1.2 Trains have a large passenger flow and are densely packed with passenger. Most of the seats, ceilings and other decorative materials are flammable. Once a fire breaks out, it can easily cause safety hazards. For safety reasons, the modules need to pass relevant tests such as fire protection and flame tests;

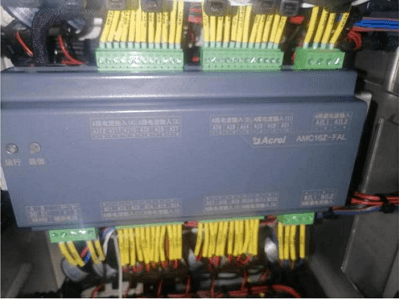

1.3 The module is installed on the mounting plate on the top of each carriage. The installation space is limited, so the module needs to be small, thin and mounted on guide rails;

1.4 It is necessary to monitor the residual current of the 4-channel air-conditioner incoming circuits and the 8-channel air-conditioning load current.

Acrel AMC16Z-FAL multi-channel current monitoring device has a compact design and can meet the real-time collection and monitoring of a total of 24 currents and 4 residual currents on sides A and B. It achieves the height of a monitoring loop in the size of a traditional instrument. The device has EN45545-HL3 fire protection report, ISO1716 flame test report, EN50155 type test report, EN50155 type test report, TB/T3139-2021 prohibited and restricted substances report, accuracy and calibration measurement report.

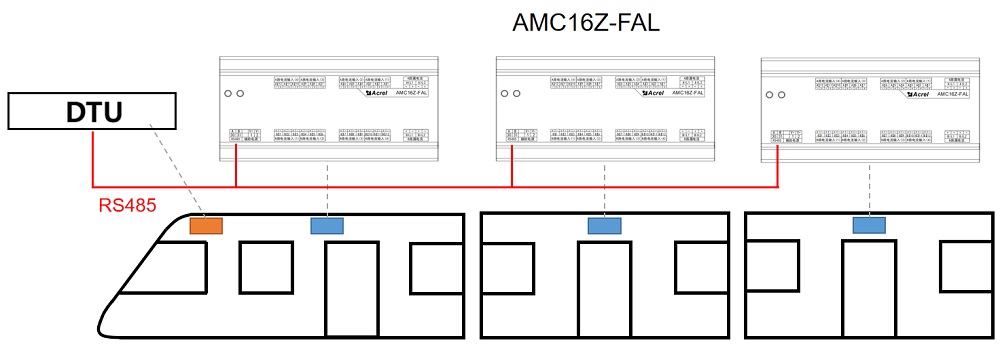

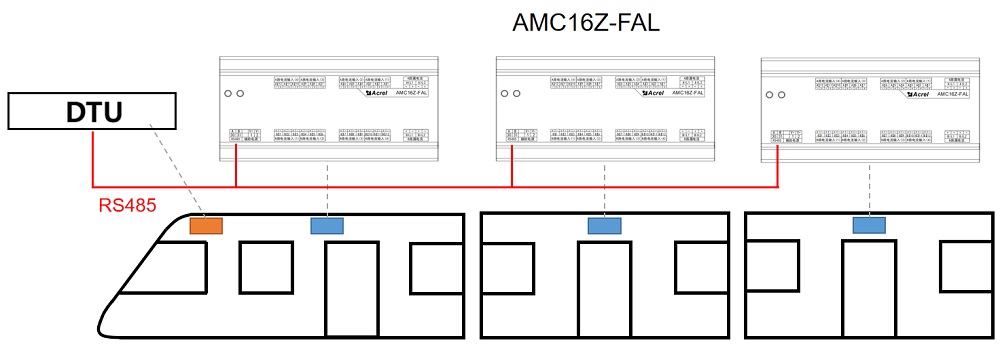

AMC16Z-FAL module is installed on the top of each carriage to measure the residual current and load current. All the data are transmitted to the data collection terminal at the front of the train through RS485 communication. After arriving at the station, the staffs remove the data collection terminal and summarize the data to the comprehensive monitoring platform. Through real-time monitoring of these electrical parameters of the air-conditioning power distribution circuit, the operating status of the air-conditioning can be judged, potential faults can be detected, and effective measures can be taken promptly when power problems occur. Make sure the air conditioning system is functioning.

The application of the intelligent substation operation and maintenance management platform can transform the existing transmission and maintenance modes into remote online diagnosis of actual operating conditions and targeted inspections based on the health status of the equipment, greatly reducing the number of operation and maintenance personnel. Conduct operation, maintenance and inspection frequency of on-site relay protection devices to improve the level of refined management of equipment. The research on remote intelligent operation and maintenance technology of relay protection is of great significance.

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

ANSI/TIA-942

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

IEC 61558-1

IEC 61558-2-15

IEC60364-7-710

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]