What’s the Highlight of Acrel APView500 Power Quality Analyzer?

What problems can we solve for you?

Data Center

Harmonic problem

A large number of nonlinear load devices such as frequency conversion equipment, UPS, switching power supplies, etc. in the data center generate a large amount of harmonics during operation, affecting the safe operation of the power distribution system of the data center.

Voltage sag problem

Voltage sag during daily power supply will cause interruption of equipment such as control or drive systems, resulting in data loss and other problems.

New Energy

Harmonic problem

DC power into AC power through the opening and closing of semiconductor power switches, which will cause harmonic problems in the process.

Voltage fluctuation problem

The uncertainty of renewable energy generation causes random fluctuations in output power, leading to grid frequency deviation, voltage fluctuation and flicker.

Voltage sag problem

The new energy power generation system connected by power electronic devices will also be affected by the DC component.

Semiconductor

Harmonic problem

Wafer machines used in chip manufacturing or variable frequency controlled semiconductor machines and other equipment will generate a large amount of harmonics, which will cause the equipment itself to fail, and even cause the production line to stop and semi-finished products to be scrapped.

Voltage sag problem

Semiconductor and LCD manufacturing are very sensitive to voltage sags. A voltage sag of 85%-90% of the rated value for 16ms may cause equipment shutdown. During a short interruption, the load is basically disconnected from the power supply system. For the semiconductor industry, both will cause equipment shutdown.

Petrochemical

Harmonic problem

The electrolytic cells, electric heaters, switching power supplies, UPS, inverters, etc. used extensively in the petrochemical industry will cause a large amount of harmonics.

Voltage fluctuation and voltage sag

The power grid may experience "power fluctuations" due to lightning strikes, ground short circuits, power plant failures, etc., which may cause petrochemical equipment to shut down, leading to production process disruptions and unplanned equipment shutdowns, causing production losses.

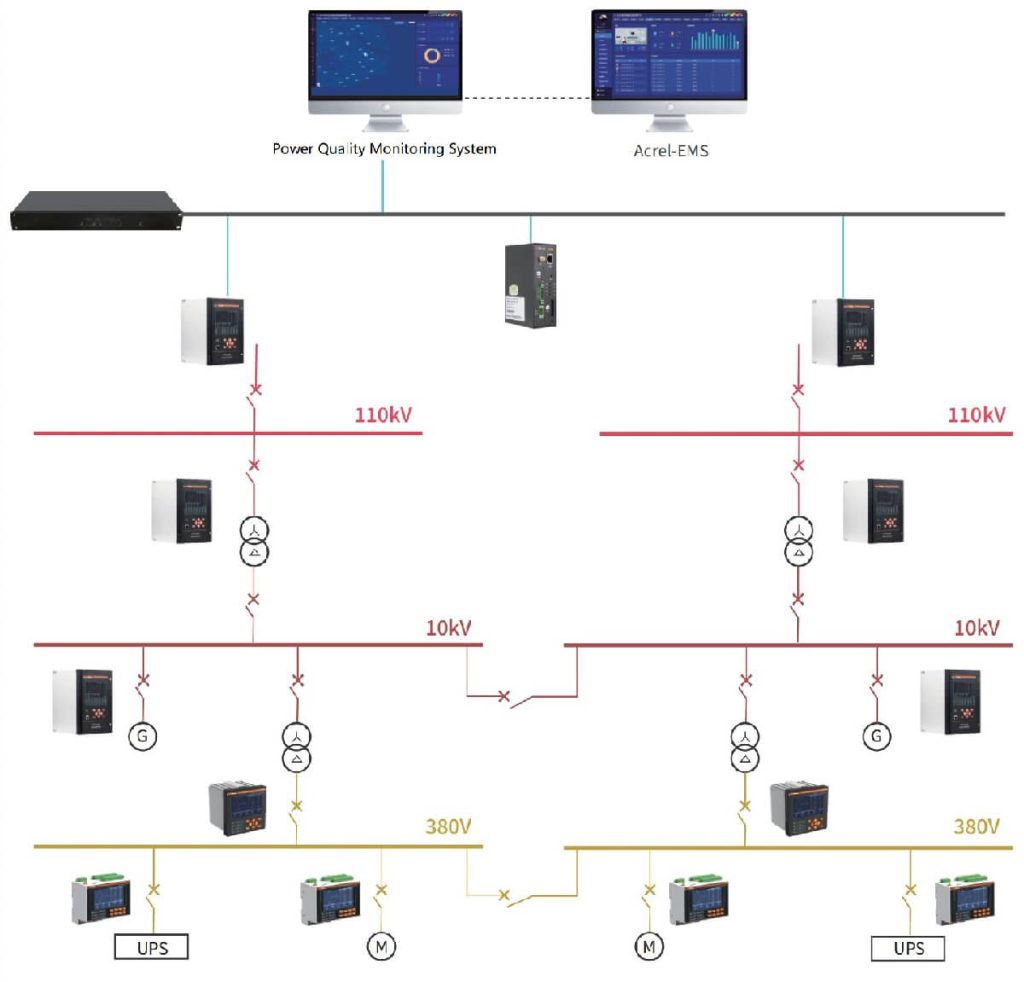

Acrel APView500 Power Quality Analyzer can be used for ≤110KV System

Photovoltaic power generation project of Tesla factory in Shanghai

This project adds distributed photovoltaic grid connection to the original 10/0.4kV system.

The distribution system originally had 4 high-voltage cabinets, 4 transformers, and 31 low-voltage cabinets.

This project uses 0.4kV grid connection, and designs 1# & 2# grid connection points.

The photovoltaic grid connection is located at the original LV distribution cabinet outlet switch.

It is necessary to install a Class A Power Quality Analyzer APView500 at each grid connection point to monitor the power quality in real time.

What’s the Function of Acrel APView500 Power Quality Analyzer?

Voltage/current accuracy ±0.1%, power accuracy ±0.2%, realizing monitoring functions such as Steady & Temporary & Transient state data, and at the same time providing strong data support for the division of responsibilities and resolution after problems occur, ensuring the reliability and safety of power supply and use

Sampling at least 1024 points per cycle and real-time waveform recording, while supporting transient voltage/current change monitoring as short as 20us.

By calling the waveform, electrical parameters and other data during the occurrence and end of the accident, the temporary sag source is determined to be located on the line side or bus side, providing direction for the user's power supply system accident analysis and helping users to quickly solve and eliminate faults.

The SEMI F47/ITIC tolerance curve is an assessment of the voltage sag/swell/interruption tolerance of semiconductor processing equipment, PLCs, inverters, computers and other equipment to prevent equipment damage or failure caused by voltage disturbances.

Fault recording can support manual trigger recording, event trigger recording, time trigger recording and host computer trigger recording; the event trigger recording can set the period before and after the fault waveform, and the sampling points of other trigger recording methods can be set. The host computer trigger recording is realized through the IEC 61850 protocol. All waveforms are stored in COMTRADE format.

It has the function of over-limit alarm output such as temporary data and steady-state data. The alarm output of different power quality faults can be freely configured, and the alarm mode can also be set to hold type, non-hold type and pulse type

| Steady state | RMS voltage and current | √ | ||

| Frequency | √ | |||

| Fundamental phase angle and vector diagram | √ | |||

| Real-time voltage and current waveform display | √ | |||

| P、Q、S、PF | √ | |||

| Ep+、Ep-、Eq+、Eq- | √ | |||

| Voltage and Current sequence components | √ | |||

| Current and voltage unbalance | √ | |||

| Voltage deviation | √ | |||

| Frequency deviation | √ | |||

| Harmonics | Harmonic voltage/current RMS | √ | ||

| (2nd -63rd) | Harmonic voltage/current ratio | √ | ||

| Total harmonic distortion(THD) of voltage/current | √ | |||

| Total demand distortion(TDD) of current | √ | |||

| Harmonic voltage/current phase angle | √ | |||

| Crest factor | √ | |||

| K-factor | √ | |||

| Odd harmonic distortion | √ | |||

| Even harmonic distortion | √ | |||

| Harmonic energy | √ | |||

| Harmonic power | √ | |||

| Interharmonics | Interharmonic voltage/current RMS | √ | ||

| (0.5-62.5th) | Interharmonic voltage/current ratio | √ | ||

| Higher harmonics | 2.5kHz~8.9kHz | √ | ||

| Voltage flicker (short-term flicker & long-term flicker) | √ | |||

| Voltage fluctuation | √ | |||

| Rapid voltage changes | √ | |||

| Temporary state | Voltage interruption | √ | ||

| Voltage dip | √ | |||

| Voltage swell | √ | |||

| Inrush current | √ | |||

| Transient state | Transient voltage | √ | ||

| Transient Current | √ | |||

| Event recorder | Temporary event | Trigger threshold of temporary event | √ | |

| Steady event | Trigger threshold of steady event | √ | ||

| Log | Record the daily operation and running conditions | √ | ||

| Waveform recorder | Event-triggered recording | Settable fault wave period | √ | |

| Manual recording | Settable recording sampling point | √ | ||

| Timed recording | Settable recording sampling point | √ | ||

| Host-triggered recording | Settable recording sampling point (supported by IEC61850 protocol) | √ | ||

| Communication | IEC61850 | optional | ||

| Modbus-RTU | √ | |||

| Modbus-TCP | √ | |||

| WebServer | √ | |||

| Timing | GPS timing(IRIG-B) | √ | ||

| SNTP | √ | |||

| Manual timing | √ | |||

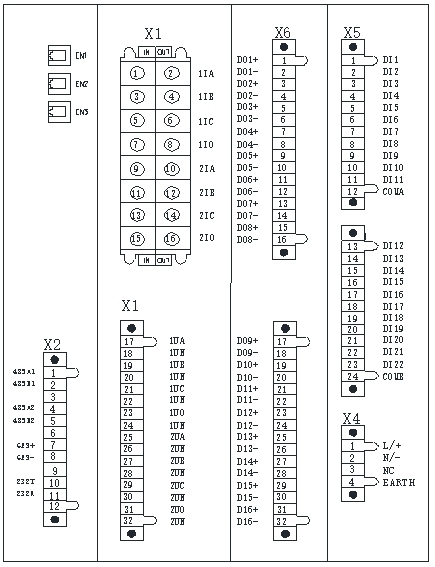

| Hardware resources | AI | 16 | Analog input | optional |

| DO | 16 | Settable digital output | √ | |

| DI | 22 | Digital input(passive contacts requiring an external power supply) | optional | |

| USB | 1 | Maintenance | √ | |

| RS485 | 2 | √ | ||

| RS232 | 1 | Maintenance | √ | |

| GPS port | 1 | √ | ||

| Ethernet port | 4 | 1 port on the front panel for maintenance and another 3 ports on the rear panel for communication |

√ | |

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

What’s the Parameter of Acrel APView500 Power Quality Analyzer?

Power supply

Rated: AC/DC220, AC/DC110V or DC48V (80% to 120%)

Permissible deviation: -20%-+20%

Power consumption:≤15W

AC Current Input

Input mode: Current Transformer input

Rated In: 5A or 1A

Measuring range: 0-1.2 In

Power consumption: ≤0.5VA (single phase)

Overload capacity: 1.2 In, continuous working, 20 times for 1 second

AC Voltage Input

Input mode: Voltage transformer input

Rated Un: 57.74V/100V, or 220V/380V

Measuring range Un: 0-1.2 Un

Power consumption: ≤0.5VA (single phase)

Overload capacity: 1.2 Un, continuous working, 4 times for 1seconds

Digital input

Rated voltage: AC/DC220V, AC/DC110V or DC48V

Input mode: Passive contacts, external power supply required

Digital output

Mechanical service life: ≥10000

Output mode: Passive contacts

Switching capacity: ≤4000W or ≤384VA

On-state current: ≥16A(AC250V/DC24V) in the continuous mode; ≥30A for a short term (200ms)

Communication port

Ethernet

Speed: 10/100M, adaptive

Type: 10/100Base—T

Compatible with TCP/IP, FTP protocol

RS485

Speed: 300-57600bps

With the optical isolation

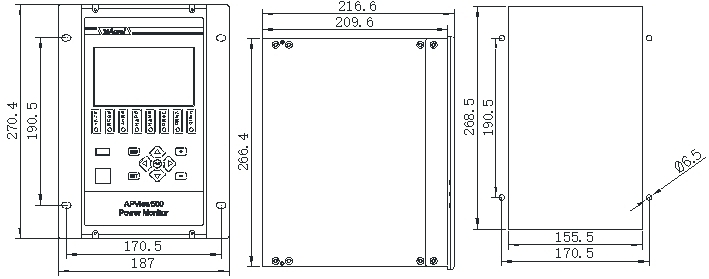

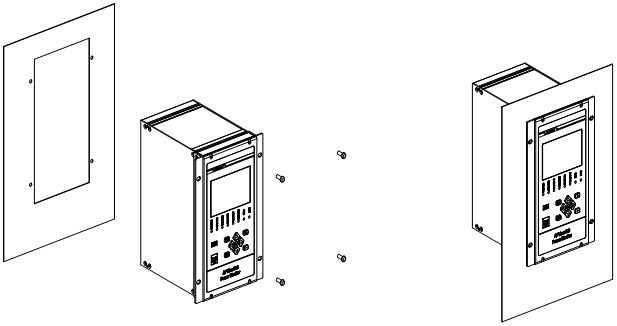

What's the Appearance of Acrel APView500 Power Quality Analyzer?

Got a Question? Get your Answer

We have our own Factory and R&D Center

Rich product series: Cloud Platform, Gateway, Protection Device, Power Meter, Transformer

CNAS, ISO14001, ISO27001, ISO9001

CE, IEC, MID, UL, EAC, ROHS, REACH

Competitive Price with High Quality

2 Years

Purchasing according to your needs, no MOQ limit

Sample takes 3 days; Bulk purchase takes 1 month

2014/35/EU

2014/30/EU

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

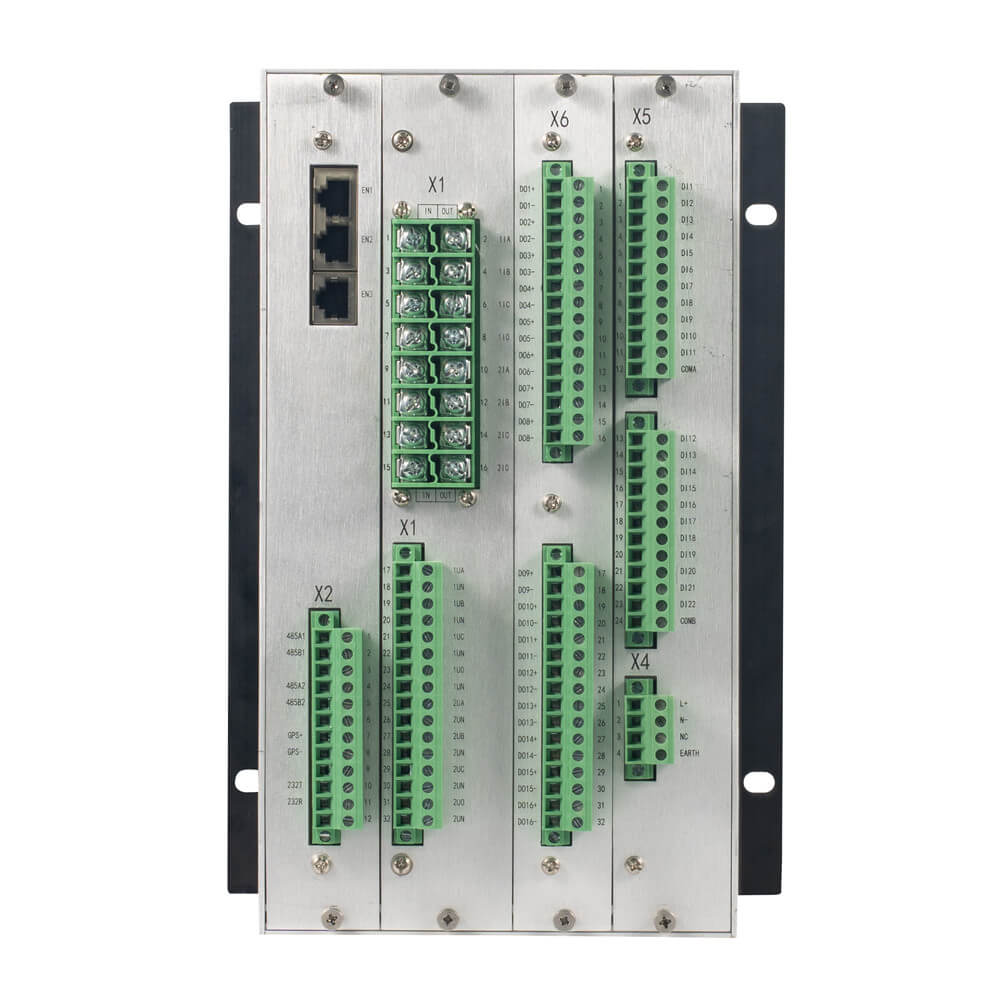

8 current input, 4 voltage input

16 DI, 10 DO

2 RS485, 1 RS232, 1 GPS

Powerful graphic programmable Logic

CE

RED

Radio Equipment Directive (RED) 2014/53/EU

CE

CE

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]